Problem

Tire and wheel-induced Quality-of-the-Ride vibrations which only occur at high speeds cannot be detected or corrected with conventional off-car equipment. The applied labor and logistics to solve these types of problems combined with warranty returns, financially impact the entire distribution chain.

Solution

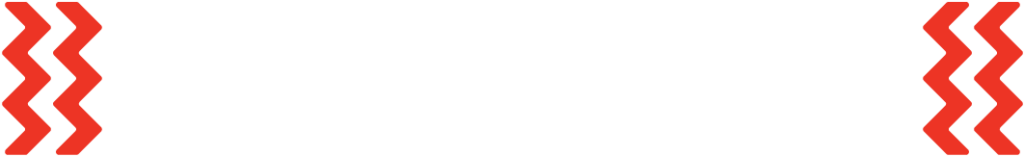

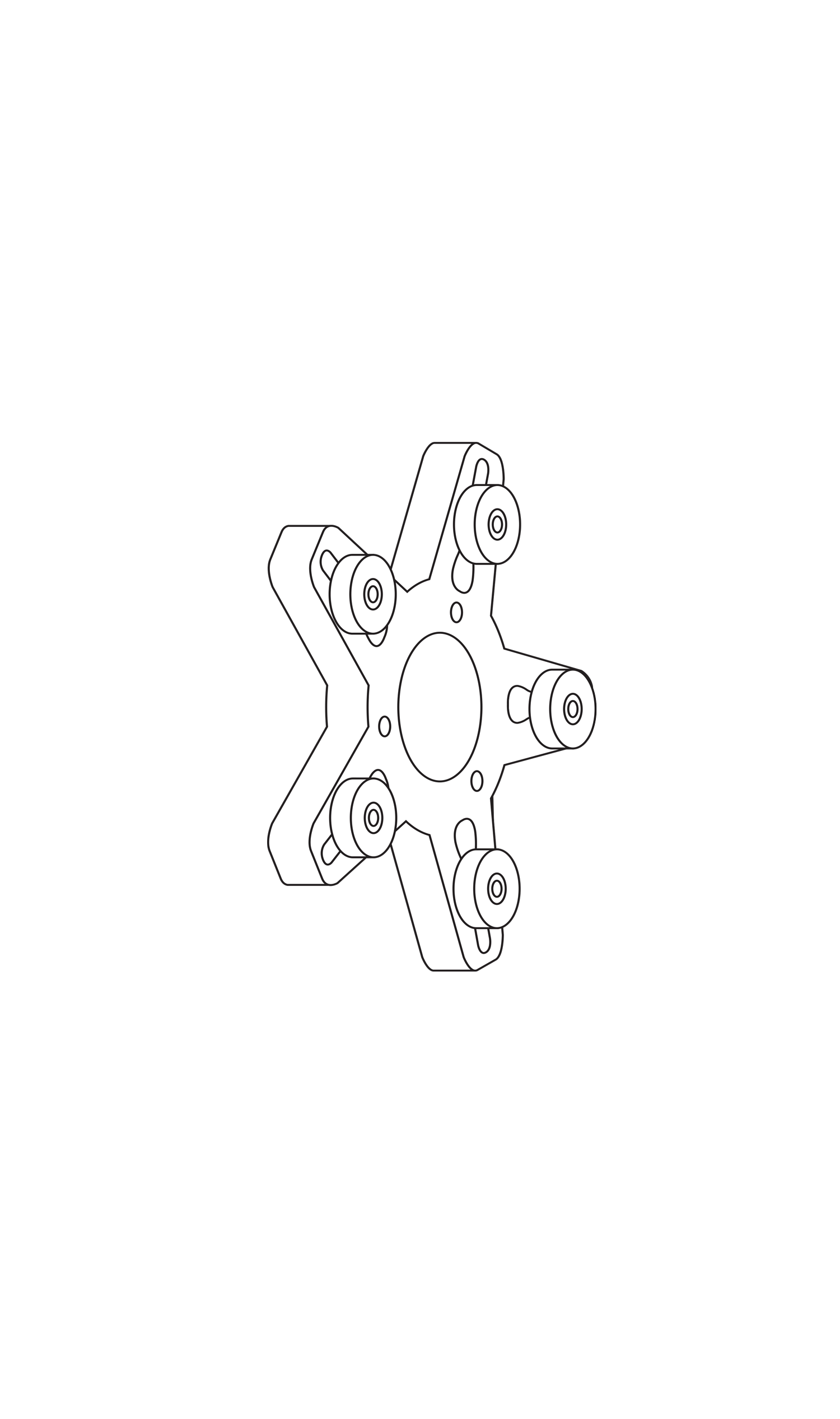

NVH Auto attaches to any lug-based truck or automotive wheel assembly in seconds. Remaining firmly attached at high vehicle speeds, sensors collect real-time data. The data is then wirelessly transmitted and analyzed via any smartphone to the cloud, resulting in a simple solution by which the technician could correct most detected problems without removing the wheels from the vehicle.

NVH AUTO

The flagship product, NVH Auto, is an innovative solution with patented features for precise rotation, balance, and alignment analysis. Its direct wheel attachment ensures accuracy and adaptability for service, manufacturing, and OEM needs. NVH Auto seamlessly integrates with moving vehicles, expanding measurement possibilities for comprehensive assessments.

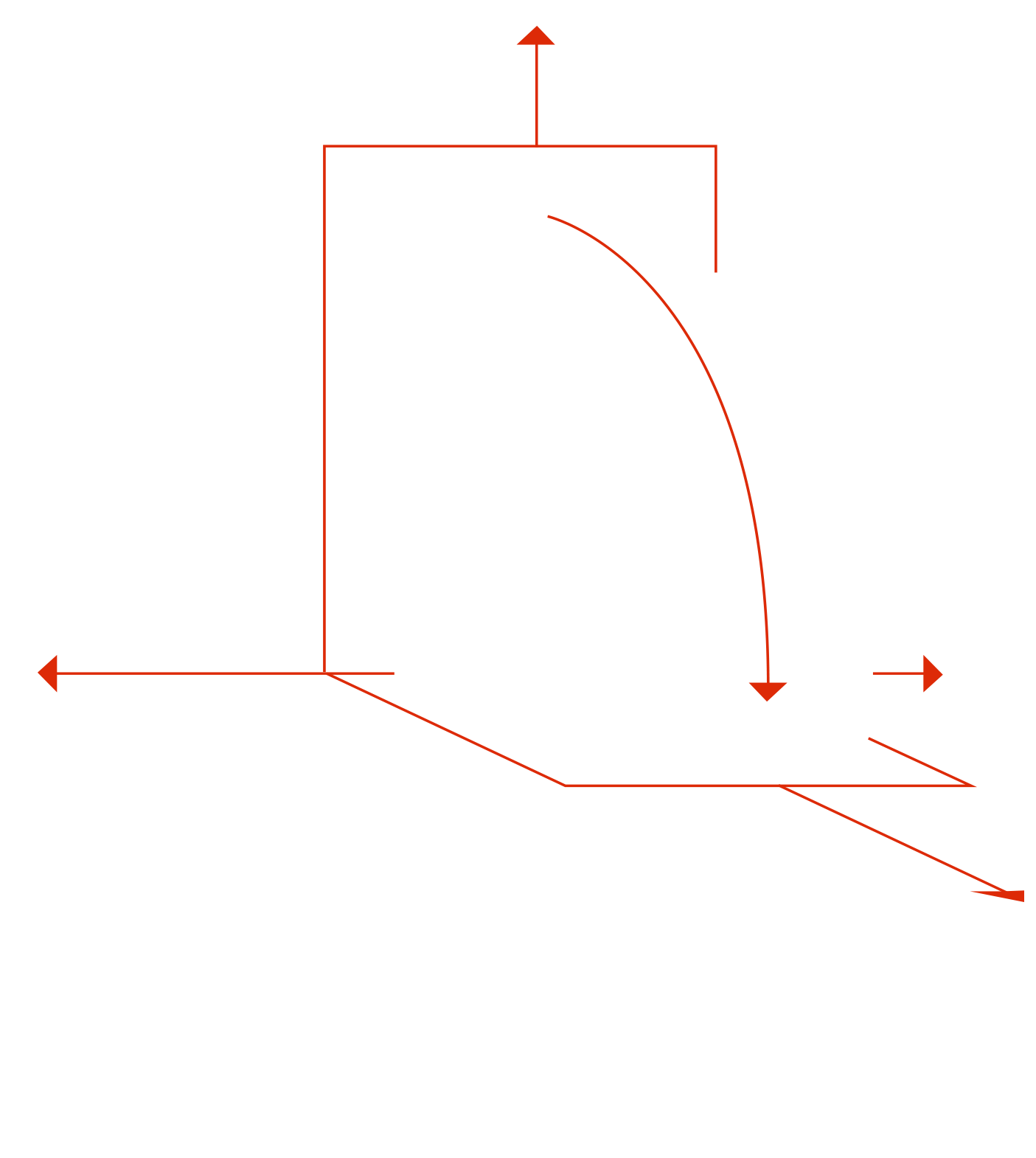

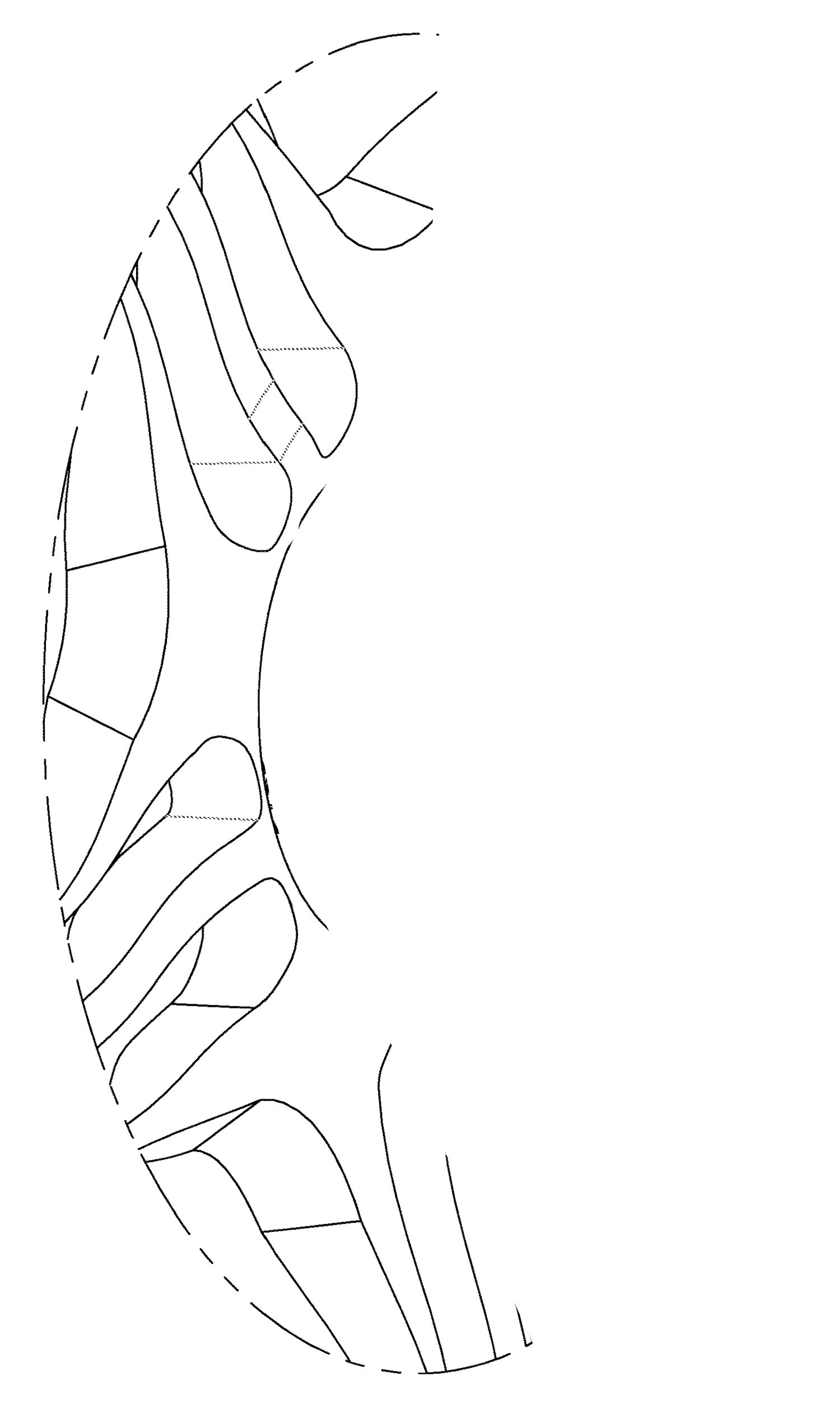

What is 3-Axis Measurement?

Where standard wheel balancing in the automotive industry is done with 2 point measurement of forward and upward force, NVH Auto is designed to add another force measurement on the X-axis. All measurements are taken while the car is in motion. This not only calibrates the single wheel, but all wheels simultaneously. The result is the ability to measure for known vehicle issues not previously detectable and diagnosable under current technology.